This ensures high productivity, process performance and economic benefits.

One of our goals is to continuously invest in technology and machinery to provide our customers with the latest technical solutions.

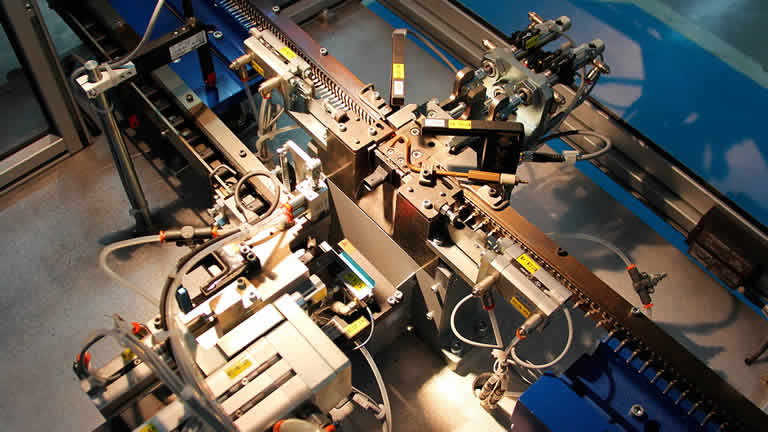

Our production site covers an area of 11,000 m², and houses 55 automatic lines that produce highly complex metal components, while reliably meeting the technical requirements of the products developed.

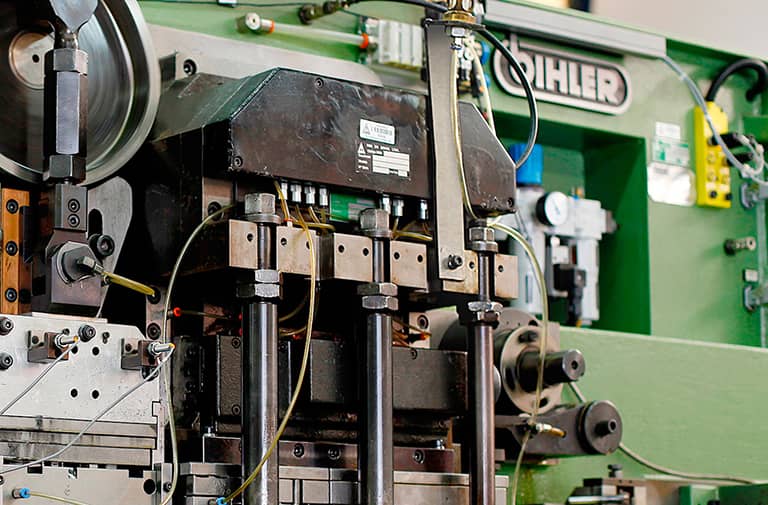

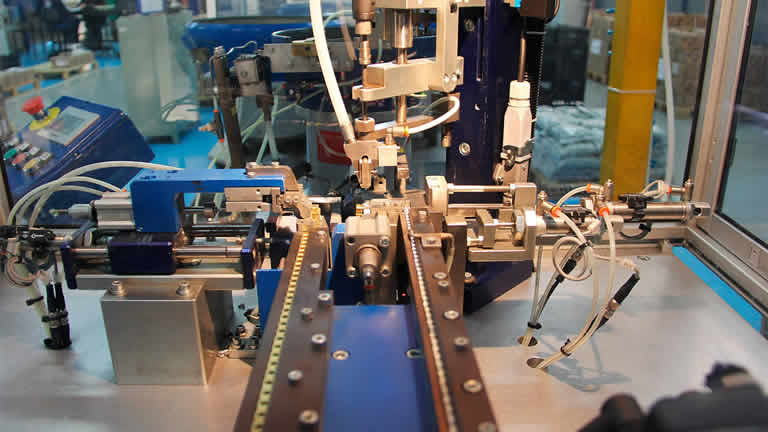

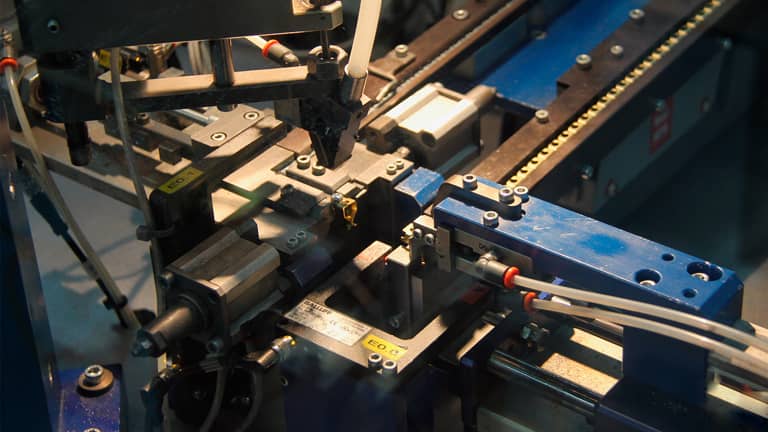

We carry out automatic assembly, either integrated into the Bihler process or on special assembly lines. Our know-how also covers development of threading and welding processes implemented directly in the stamping process, either in a press or in a Bihler machine.

Technologically advanced machines capable of creating complex geometries and performing complex operations at high production rates and with constant precision.

Bihler technologies can automatically shear, shape, bend, weld, rivet and assemble numerous components, even extremely complex ones made of different materials, on a single machining centre and in a single step.

M.S.Ambrogio do Brasil's expertise and know-how in tooling design and manufacture is able to exploit the full potential of these machines to achieve flexibility, precision and high production rates.

Thanks to more than sixty years of partnership with Otto Bihler Maschinenfabrik and a continuous exchange of information and feedback between engineers on both sides, M.S.Ambrogio now has enormous experience and knowledge of this construction technology.

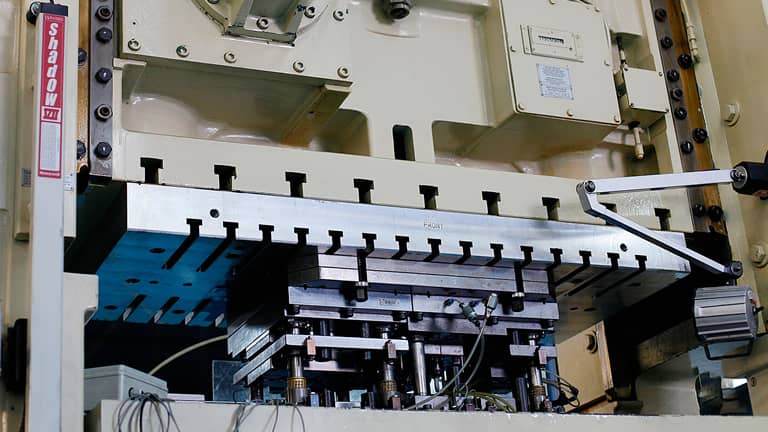

M.S.Ambrogio do Brasil has a large fleet of Bruderer high-speed automatic presses, ranging from 30 to 60 tonnes, which guarantee maximum quality performance while achieving high production speeds.

Here too, as in production with Bihler technology, all equipment is designed, manufactured and tested by M.S.Ambrogio do Brasil to its own production standards in order to guarantee absolute finished product quality.

Our machine fleet has high tonnage presses, by Minster and SEYI, from 125 up to 250 tonnes for precision progressive stamping.

All presses at M.S.Ambrogio do Brasil offer high performance, quality and production efficiency. They offer excellent product and process performance, thanks to the possibility of adjusting the processing standards in relation to the characteristics of the part to be produced.

M.S.Ambrogio do Brasil's technology is able to assemble metal/plastic components, thus providing the customer with the final solution, with time and cost benefits.